Eyes on safety

- By Natalie Hildt Treat

- •

- 04 Mar, 2021

A conversation with NRC's resident inspector at Seabrook Station

C-10’s ability to carry out our mission to help protect people and the natural environment depends on good relationships and trust. Throughout our three decades of operating the Citizens Radiological Monitoring Network and tracking safety and security matters at Seabrook Station, some of the most important relationships we’ve had have been with the two resident inspectors who work for the US Nuclear Regulatory Commission (NRC).

Each of the nation’s 94 commercial nuclear plants has at least two NRC resident inspectors on site whose job it is to monitor daily operations, conduct inspections and oversee major projects such as refueling and maintenance periods. Their terms are limited to seven years before they are moved to a new plant.

Christopher Newport is the senior resident inspector at NextEra Energy’s Seabrook Station, the role he began in the fall of 2020. The other inspector is Travis Daun, who came to Seabrook in the summer of 2019. Newport had previously served as Seabrook’s resident inspector for two and a half years before being promoted to senior resident inspector at the Diablo Canyon nuclear power plant in San Luis Obispo, California in 2016.

“Chris Newport was a student in one of the classes I taught while working at the NRC,” said David Lochbaum, a nationally-recognized nuclear safety expert who serves on C-10’s Advisory Board. “Two types of students stuck in my memory—those well above average and those way behind. Chris was solidly in the former group. I was glad to see he was the senior resident at Seabrook,” said Lochbaum.

Newport joined the NRC in 2008 as a project engineer in the Region I office near Philadelphia. Before his tenure at NRC, Newport served in the US Navy as a nuclear submarine officer in charge of the sub’s reactor. He holds a bachelor’s degree in control systems engineering from the United States Naval Academy and a master’s degree in engineering management from Catholic University.

As executive director of the nuclear safety group C-10, I recently had the chance to speak with Newport by phone to learn more about what his job entails and ask what he thinks about how Seabrook is operated. The following is a summary of our conversation, edited for clarity.

NT: Could you please describe a typical day in your work at Seabrook Station?

CN: We are generally on-site four to five days a week. The other inspector, Travis and I, try to stagger our days a bit during the COVID pandemic, taking advantage of remote telework technologies to carry out a portion of our work. One of our primary responsibilities is emergency response, we try to take reasonable precautions to ensure that we are both not exposed to COVID.

We are also required to do at least 50 hours of weekend and overnight hours per year, but most years we far exceed that. We also respond to the site, regardless of the day or hour, in the event of an unplanned shut-down or other safety event.

During a typical day, what we primarily do are the baseline inspections—general inspections that all sites receive throughout the year. I arrive on-site around 6 a.m., review the control room logs and the condition reports over the last 24 hours, and get a sense of anything that has happened overnight and the plan for the day.

As an aside, anytime an issue is discovered on-site, Seabrook staff create what they call a condition report. They are entered into a formal system for disposition and resolution. This process of “problem identification and resolution” is critical to the safe operation of these facilities.

We attend the 6:30 am Plan of the Day management meeting to find out about the work for the day and any issues to note. Every single day that we are on-site we go into the control room and walk down the control boards, look for any alarms, chat with the operators, and talk with them about what’s challenging them for the day. For the remainder of the day we do walk-downs of the plant, attend licensee meetings, observe maintenance activities, and conduct various paperwork reviews. There are items that need to be reviewed weekly, monthly and quarterly.

I’ll watch Seabrook personnel do maintenance, surveillance tests, equipment walk-downs, and if there’s an issue, I’ll go physically look at it. I’ll go into the security areas and any other areas of the plant that we think may be of interest.

As NRC inspectors we have what’s called “unfettered access.” By regulation, the licensee cannot prevent us from accessing any area of the site at any time. Unless our personal safety is at risk, we are able to access everything on site completely independently. Onsite, it’s about physically looking at things and talking to people, not just what the senior managers present in meetings or briefings. “Trust but verify” is a saying that you will often hear used in the nuclear industry.

With only two on-site inspectors though, we can’t look at everything that they do at every moment of every day, so we risk-inform the conduct of our work. We know what’s important, and what’s more important. The NRC relies on probabilistic risk assessment (PRA) to inform much of how we do business. These PRA models highlight what is most important at the plant and can tell us that we need to go look at that pump or valve every week versus another piece of equipment that we may only need to inspect on a monthly basis.

Another example, NRC guidance will say that we have to look at 25 maintenance work jobs a year, but they give us the flexibility to choose which ones and when. We are able to pick the ones we determine are more important based on our day to day site specific knowledge and the insights we glean from the PRA models. It’s a good system that ensures that we use our resources as efficiently and effectively as possible.

NT: How does Seabrook Station compare to other plants where you have worked? Tell me a little about how the NRC handles safety issues.

CN: The NRC has four columns of performance for operating commercial nuclear reactors. Seabrook is currently in Column 1, the highest Column. Column 1 is representative of extremely safe operation, with only low-level inspection violations and plant events identified. Plants operating in this column far exceed the minimum standards we have determined are required to assure public safety.

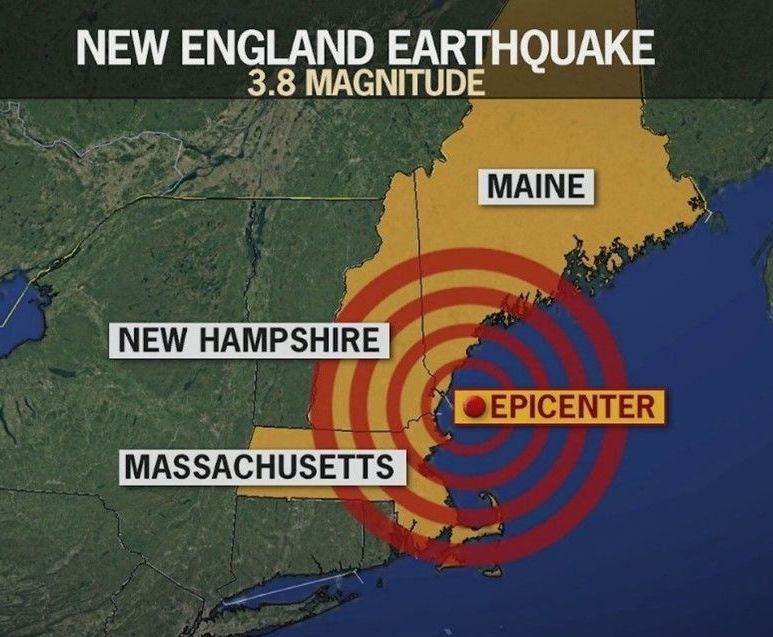

Column 4 on the other hand, indicates that degraded performance of the plant has been identified that if not corrected, could result in the NRC deeming the plant unsafe to operate. For example, Pilgrim Station (in Plymouth, Mass.) was in Column 4 because the plant had what we determined to be a higher number of performance issues and plant events that pushed them closer to that line that we have drawn in the sand for maintaining safe operation.

When a plant is in this column, they receive heavy scrutiny from the NRC and public stakeholders. To Pilgrim’s credit, they were able to make substantial changes to the plant equipment and the way that they conducted day to day operations that gave us the confidence to move them back to Column 1. (Pilgrim ceased reactor operations in May 2019 after returning to Column 1). It’s important to note that even in Column 4, the plant is operating above the threshold of what the NRC has determined to be safe.

Over the years, the industry has learned how to operate at a very high reliability rate, as what is good for safety often closely aligns with what is good for their business. It’s become increasingly uncommon for plants to move through the columns, but it still does occur.

NT: In May and June of 2020 there were a pair of unplanned shutdowns or “SCRAMs” at Seabrook. We heard that was a technical issue and the public was never in danger when control rods automatically inserted and halted the nuclear reaction.

CN: That’s correct, the reactor was shut down by operators as designed when the issue manifested itself. There was a circuit card connector issue in the rod control system, causing a malfunction in the system. Seabrook worked with the vendor to find out why this happened and to prevent it from happening again. Seabrook has also provided this knowledge to the industry as a whole to make sure that any plants potentially susceptible to the same issue are aware of it and can make changes.

That being said, unplanned shutdowns of the reactor are inputs into our assessment process as they can be representative of broader concerns with how the plant is being operated. When plants start to have multiple unplanned shutdowns, they feed into our assessment process and can start to trigger the movement towards Column 2 and beyond. In Seabrook’s case, it was an isolated incident. They have not had any other unplanned shutdowns to date and thus remain in Column 1.

NT: Can you comment on the working relationships with the NextEra Energy staff at the plant?

CN: NRC inspectors need to have a close working relationship with plant operators based on trust and a mutual desire for nuclear safety above all else. There always needs to be what I call “regulatory tension” between the regulator and the plant operator, but the relationship is ideally based in trust, openness, and respect. As far as how that works, it sometimes depends on the actual plant. Seabrook management listens when we raise concerns, even if they are low level and not representative of violations of our requirements.

High performing plants tend to have a very cordial relationship with the inspectors; they’ll listen and make the corrections even when they aren’t required to, as Seabrook tends to do. It’s when a lot of little things aren’t getting taken care of, when worker morale is not high, that’s when you can tell there may be problems coming.

We look at that aspect of an engaged workforce and what we call “safety culture” very closely. Seabrook has a strong safety culture right now (learn more about it here). That being said, if an issue comes up that’s a violation of our standards, if Seabrook is resistant to taking the required actions to correct the issue, we will not cease from holding them accountable.

NT: Can you talk about a safety issue that you’ve raised with the licensee?

CN: A good example is ASR (alkali-silica reaction, the concrete degradation affecting all safety structures at Seabrook). It’s a large challenge to address and is a first-of-a-kind in the industry, even though it is a well-known phenomenon outside of the industry.

A number of years ago, when I was here as the resident inspector, Seabrook was initially reluctant to address the building deformation aspect of ASR, which is now a large part of the ASR monitoring program on-site. I actually had water drip on my hardhat while walking through the plant; further investigation of the water source revealed signs of bulk deformation of a safety related building on-site. Additional inspection revealed signs of something unexpected happening with many of the structures on-site that had not been previously recognized by the licensee.

It took some NRC prompting initially for them to start fully addressing the issue as we felt was appropriate. That regulatory tension that I talked about is important. Even the best performing organizations are susceptible to groupthink, loss of the big picture, etc. There are no shortages of examples of that phenomenon outside of the nuclear industry. A good regulator can help to identify those issues if and when they crop up to hopefully avoid them becoming bigger ones down the road.

NT: What is the process if you see a violation or have a concern? How does that get reported, and how can the public be sure that it would be properly elevated and followed up on?

We characterize inspection issues using what we call the Significant Determination Process. If we find an issue of concern, we work through our process to determine if it was reasonably within Seabrook’s ability to foresee and correct, and if it was, to determine its safety significance. If the issue is more than what we call “minor” we call it a finding or violation.

We will perform a PRA based risk assessment and characterize it by its safety significance using our color-based system (Green, White, Yellow, Red). Seabrook is required to correct any violation that we identify and anything that we determine to be greater than Green safety significance will end up receiving a great deal of scrutiny by both the licensee and us.

All Green findings or greater are documented in our inspection reports which are publicly available. (Also see Seabrook’s Quarterly Performance Summary). I always strive to make the write-ups very clear so that a reasonably informed member of the public can understand the issue and why we came to the conclusions that we came to regarding its risk significance.

If there are greater than Green findings, those write-ups are very detailed. As the plants have learned to become more efficient at operations, these greater than Green findings have become unusual. There are maybe only a handful a year throughout the industry.

What the public doesn’t see are the things that are minor or just observations; we’ll generally have many of these each quarter. This week for example I observed five or six low-level issues that they fixed, these are things as simple as a ladder not stored in its proper location or a used rag that a watchstander accidently left behind while doing their rounds.

We are out there every day along with the licensee constantly looking for these small things. At the high-performing sites as Seabrook currently is, resident inspectors are really digging into the weeds. If you're focused on the little things, the big things tend not to happen.

NT: What are the things about Seabrook Station that give you the most confidence?

CN: They’ve put the money into the plant, including a lot of the physical equipment even when not absolutely required by regulation. They have good management teams and the right safety focus. Safety culture, employee engagement—those things are kind of intangible. There’s a positive culture at Seabrook which in my opinion is the most critical part of high performing operation.

NT: Back to Seabrook’s concrete. What assurance do we have that NextEra Energy is complying with what they’re supposed to be doing as far as enhanced concrete monitoring protocols that were ordered by the Atomic Safety and Licensing Board (ASLB) last fall, and are now part of the plant’s operating license?

CN: It’s now part of their licensing basis, including the orders by the ASLB. They’re required by law to comply with that and we hold them accountable. We have integrated ASR into our safety inspections and are continuously monitoring the licensee’s actions with respect to it. When new conditions develop, we inspect the licensee’s actions to address them and make sure they stay in compliance with their license.

ASR can be highly technical. I have spent a good bit of time learning about the technical details of the phenomenon (including reading some of the information presented by C-10’s expert, Dr. Saouma to the ASLB) but as the senior resident inspector, I am a generalist. I sometimes don’t have the level of expertise to understand the detailed calculations and analysis techniques that are employed when analyzing these structural engineering issues.

Part of my job is making sure that I know enough to know when to ask for help. I frequently engage with our structural experts at our regional office in King of Prussia, Pennsylvania and at our Headquarters office in Rockville, Maryland when my limits are reached. Those experts engage directly with the engineers working on ASR at Seabrook to ensure that we have a full understanding of what the site is doing and whether it is in compliance with their license.

NT: During your years at Seabrook, you’ve worked a fair amount with C-10. Can you comment on that relationship?

CN: My message is that your group and groups like yours are critical in a high functioning society. As the federal regulator charged with ensuring commercial nuclear reactor safety, we oversee Seabrook. But the public, including C-10, in a sense oversees us. I am proud to work for the NRC and strongly believe that we are a dispassionate and effective regulator, but as I alluded to earlier, every organization is susceptible to mistakes and missteps.

As federal regulators, we ultimately work for the public and that is something that in my experience is taken very seriously within the NRC. We do everything that we can to be as transparent as possible so that the public and groups like yours can observe what we are doing and understand why we are doing it. That transparency is critical.

Follow us